1、 Overview

Used to measure the thermal conductivity of various homogeneous plate shaped insulation materials and non good thermal conductivity materials. The measuring instrument adopts a microcomputer automatic control system, which has the advantages of automatic control of the experimental process, automatic completion of data collection, and generation of reports, and has a high degree of intelligence. It is currently an ideal choice for conducting such testing projects in China.

2、 Testing items

Used to measure the thermal conductivity of various homogeneous plate shaped insulation materials and non good thermal conductivity materials.

3、 Principle

Under steady-state conditions, within the central measuring area of the protective hot plate device, a one-dimensional constant heat flow is established in a uniform plate-like specimen with parallel surfaces, similar to an infinite plate bounded by two parallel uniformly heated plates.

4、 According to standards

GB/T10294-2008 "Determination of steady-state thermal resistance and related characteristics of insulation materials - Protective hot plate method"

GB/T 3399-1982 "Test method for thermal conductivity of plastics - Thermal protection plate method"

5、 Technical parameters

1. Model: DRCD-3030

2. External dimensions (length x width x height): 1020x650x1480 (mm)

3. Sample specifications: (metering) 150x150 (mm) - (protection) 300x300 (mm)

4. Test piece thickness: According to national standards ≤ 37.5 (mm), clamping thickness ≤ 50 (mm)

5. Measurement range of thermal conductivity: 0.0100~2.0000W/(m.k)

6. Cold plate temperature: 3 ℃~90 ℃

7. Hot plate temperature: ≤ 120 ℃

8. Test accuracy: ≤ ± 2%

9. Test repeatability: ≤ ± 1%

10. Equipped with power: 3Kw 220V

6、 Test device structure

Adopting the dual specimen protection hot plate method (GB10294-2008), it consists of a microcomputer automatic control system, a metering heating unit, a cold plate unit, a protection unit, an external protection unit, a measurement system, a clamping system, a refrigeration mechanism, etc.

1. Microcomputer automatic control system

The computer outputs signals through I/O and D/A conversion to control the corresponding execution components, achieving functions such as temperature control, calculation, temperature acquisition, printing test reports, and displaying process curves. The human-machine dialogue window displays temperature values on all sides and has a self diagnostic function.

2. Measurement heating unit

Using aluminum plate as the heating panel, due to its high thermal conductivity, makes the heating plate surface temperature more uniform and has less thermal inertia, making the measurement results more accurate.

3. Cold plate unit

Using a constant temperature water tank to control the temperature of two cold plates, the temperature of the cold plates can be set and automatically controlled by a microcomputer, which is conducive to controlling the temperature difference between the two sides to be similar.

4. Protection unit

Using the same panel material as the metering heating unit, the temperature difference on both sides of the gap is precisely controlled to reduce testing errors.

5. External protection unit

Using a protective sleeve made of cork as the external protective unit makes the experimental environment conditions more stable, which is beneficial for improving testing accuracy.

6. Measurement system

Using the more stable Dallas 18B20 digital temperature sensor and high-precision DC power sensor, the data collection results are more accurate.

7. Compression system

Using pneumatic technology, the test piece is automatically compressed using a cylinder, without the need for manual adjustment of the clamping force, making the clamping of the test piece very convenient.

8. Refrigeration mechanism

It can quickly reduce the temperature of the cold plate and detect the average temperature of the specimen below room temperature, making the detection range larger and not affected by environmental temperature.

7、 Operating instructions

1. Manual operation

Connect the power supply, press the "Power" button on the control cabinet, and the power indicator light will be on. Click the "Left On", "Left Off", "Right On", and "Right Off" buttons to open or close the specimen clamping device, so that the experimenter can install and disassemble the specimen.

2. Microcomputer operating system

① Connect the microcomputer system, turn on the power, start the computer to enter the WinXP operating system, double-click the "thermal conductivity" icon to enter the automatic control system.

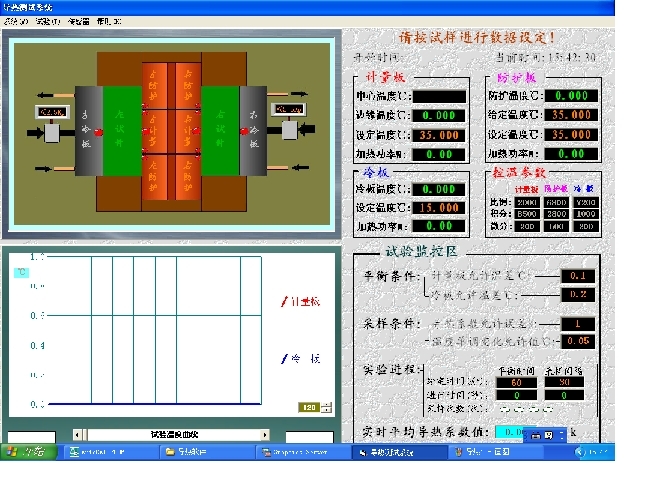

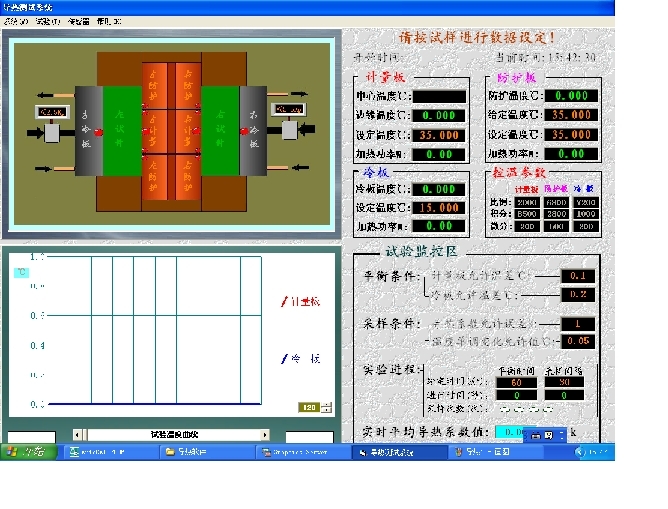

② Click the "Exit" button to exit the operating system, and click the "Test" button to enter the main screen (see Figure 2).

(Figure 2)

③ Click on "Data Settings" under the "Experiment" menu to perform data settings (see Figure 3 and Figure 4).

(Figure 3)

(Figure 4)

④ Click on the "System" menu in the data settings window to exit and return to the main screen.

⑤ Click on the main menu "Temperature Sensor Detection" to monitor whether the sensor is functioning properly:

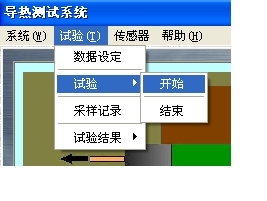

⑥ Click "Start" under the "Experiment" menu to enter the experimental state (see Figure 5).

(Figure 5)

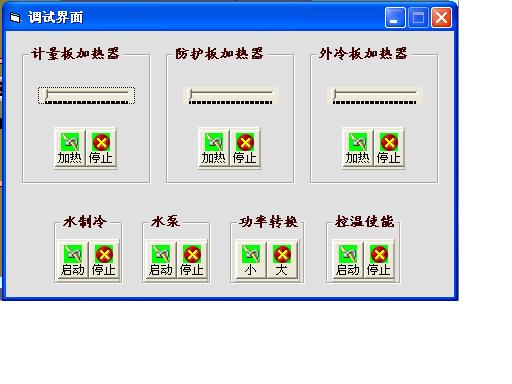

⑦ Click "Debugging" under the "System" menu to open the debugging interface (see Figure 6 and Figure 7).

(Figure 6)

(Figure 7)

⑧ If the given temperature of the cold plate is ≥ (ambient temperature+10) ℃, the water cooling "stop" button needs to be pressed. Other items should remain unchanged according to the factory settings. If there are any changes, the on-site debugging by the service personnel shall prevail.

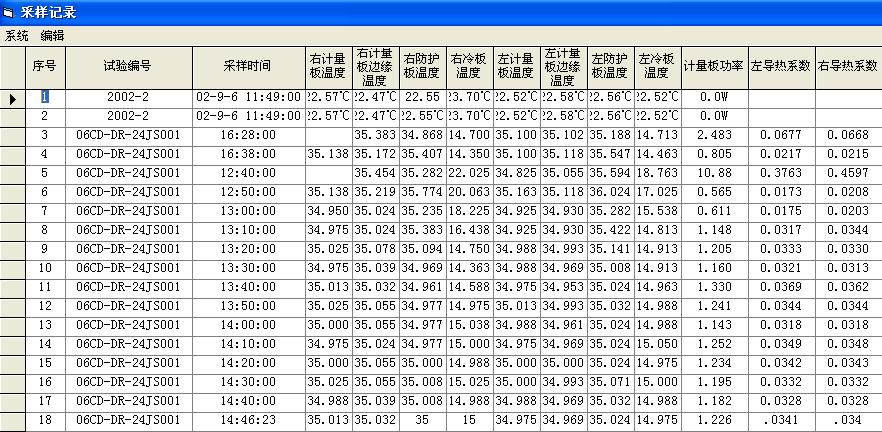

⑨ Click on "Sampling Record" under the "Experiment" menu on the main screen to enter the testing record screen (see Figure 8).

(Figure 8)

In the test record screen, you can view the experimental data throughout the entire process and delete historical data.

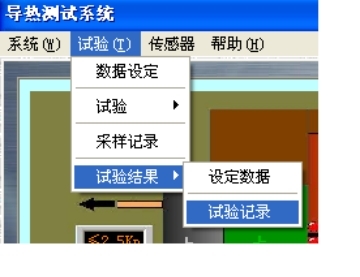

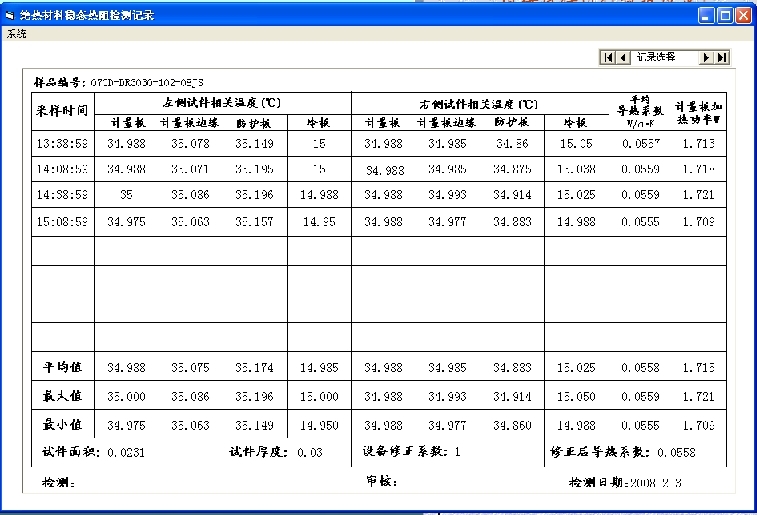

⑩ Click on "Test Results" and "Test Record" under the "Test" menu on the main screen to enter the test record screen (see Figure 9 and Figure 10).

(Figure 9)

Click "Record Selection" in the test record screen to select the original records of each experiment, with the last record being the original record of the last experiment. Press "Print" under the "System" menu on the screen to print the selected original record.

(Figure 10)

The experiment will automatically end. If the experiment is stopped during the process, click "End" under the "Experiment" menu in the main screen to exit the experiment status (see Figure 5).

Click "Exit" under the "System" menu in the main screen to exit the main screen.

Remove the specimen and disconnect the power to end the experiment.

Organize experimental reports.

8、 Precautions

1. Special attention should be paid to cleaning and rust prevention maintenance after the experiment;

2. After the installation and debugging of the equipment, the operator should regularly check whether the grounding protection of the control box is normal;

3. The environment and equipment should be kept generally clean, with an ambient temperature of 18-25 ℃ and a relative humidity of<50%;

4. The antifreeze or water in the water tank should be kept clean and replaced regularly;

5. Regularly check the power sensor;

When the entire machine is stopped for a long time, the main power plug should be unplugged, and attention should be paid to rust prevention and dust prevention.

9、 Main Component Configuration Table

|

Number |

name |

Specification/model and purpose |

quantity |

producing area |

|

1 |

Control cabinet body |

Equipment as a whole |

one |

Our company |

|

2 |

Refrigeration mechanism |

1/3P、For water tank temperature control |

one |

Aspara, Italy |

|

3 |

Data collector |

Data collection and control |

one |

Beijing Shuangnuo |

|

4 |

Measurement heating unit |

Realize the measurement of temperature field |

two |

Our company |

|

5 |

Protection unit |

Implement protective temperature field |

two |

Our company |

|

6 |

External protection unit |

Lateral temperature field protection of hot plates |

one |

Our company |

|

7 |

Heating element |

Thin film, for heating purposes |

one |

Our company |

|

8 |

Cold plate unit |

Aluminum plate, achieving cold surface temperature field |

two |

Our company |

|

9 |

Compression system |

Clamping for specimens |

two |

Our company |

|

10 |

Pneumatic components |

Used to control the clamping force of the specimen |

two |

Taiwan Yadeke |

|

11 |

water tank |

Used for temperature control of cold plates |

one |

Our company |

|

12 |

circulating pump |

RS25-6、Cold plate water circulation |

one |

Weile |

|

13 |

temperature sensor |

DALAS18B20 (Digital) |

52 points |

United States |

|

14 |

module |

Temperature collection |

one |

Our company |

|

15 |

micro-computer system |

Data collection and automatic control |

one |

brand |

|

16 |

Air pump |

Provide air source |

one |

Shanghai Jiebao Mute |

|

17 |

Measurement power supply |

Used for temperature control of metering heating units |

one |

Shanghai Fudan |

|

18 |

Protective power supply |

Used for temperature control of protective units |

one |

Hangzhou Xizi |

|

19 |

AC voltage regulation module |

Used for water tank temperature control |

one |

Hangzhou Xizi |

|

20 |

Measurement power sensor |

1906B、Measurement of metering power |

one |

|

Tel:15231476158

Tel:15231476158 Mailbox:948064885@qq.com

Mailbox:948064885@qq.com QQ:948064885

QQ:948064885 Add:Room 211, Juntai Fortune Plaza, Shuangtashan Town, Shuangluan District, Chengde City, Hebei Province

Add:Room 211, Juntai Fortune Plaza, Shuangtashan Town, Shuangluan District, Chengde City, Hebei Province