Manual operation box displayed on the operation interface

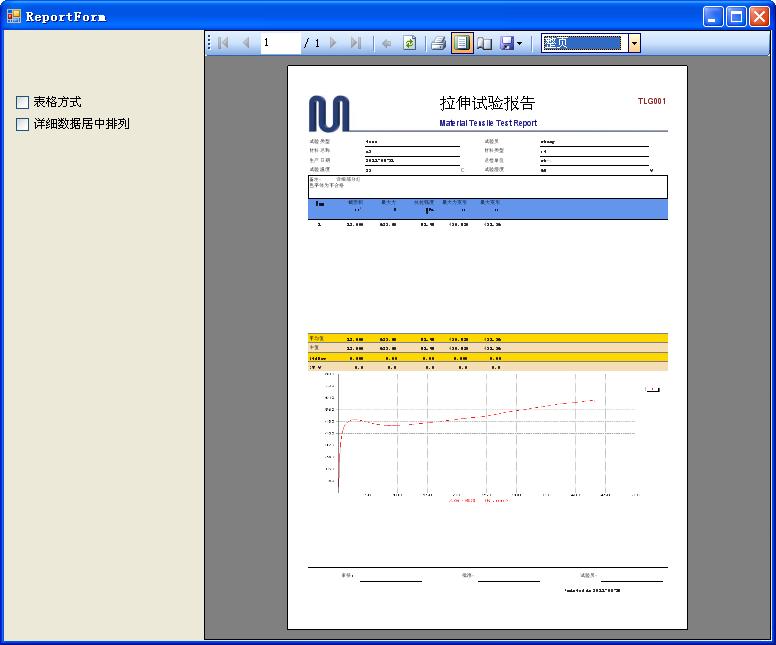

Test result report chart

1、 Overview

This machine can perform tensile, compression, bending, tearing, 90 ° peel, 180 ° peel, shear, adhesive force, pull-out force, elongation and other tests on rubber, plastic, foam materials, plastics, films, flexible packaging, pipes, textiles, fibers, nanomaterials, polymer materials, composite materials, waterproof materials, synthetic materials, packaging belts, paper, wires and cables, fiber optic cables, seat belts, safety belts, leather belts, footwear, tapes, polymers, spring steel, stainless steel, castings, copper pipes, non-ferrous metals, automotive parts, alloy materials, and other non-metallic and metallic materials.

2、 Host specifications

1. High precision force sensor: 0-20kN (optional in the range), with force accuracy within ± 0.1%;

2. Capacity segmentation: Seven levels throughout the entire process: × 1, × 2, × 5, × 10, × 20, × 50, × 100;

3. Adopting high-precision 24 bits A/D, sampling frequency of 200Hz, and full force resolution of 1/1000000;

4. Power system: Navigation servo motor+Navigation servo driver+Ball screw+Smooth rod linear bearing+Synchronous belt drive;

5. Control system: Adopting Command control method to make control more precise;

6. Speed control range: 0.01~500 mm/min;

7. The Zhonglian board adjustment has fast coarse adjustment and slow fine adjustment functions, which automatically return to the origin and store after testing;

8. Data transmission method: USB transmission;

9. Display method: UTM107+Win7/10 testing software computer screen display;

10. A concise linear dual calibration system with one gear throughout the entire process and a precise seven gear force throughout the entire process;

11. The luxury testing interface software can achieve control modes such as constant speed, positioning displacement, constant load (with adjustable holding time), constant load increase rate, constant stress increase rate, and constant strain increase rate. In addition, multi-stage control modes can meet different testing requirements;

12. Testing space: The testing width is about 400 mm (standard specification)

Upper and lower space of the connecting plate: 900 mm (excluding fixtures) (standard specifications);

13. Full displacement: Encoder 2500 P/R, improving accuracy by 4 times;

14. The LINE DRIVE encoder has extremely strong anti-interference ability, with a displacement resolution of 0.001mm;

15. Safety devices: overload emergency stop device, up and down travel limit device, leakage automatic power off system, automatic breakpoint stop function.

3、 Software Function Introduction

The testing machine measurement and control system is designed specifically for microcomputer electronic universal testing machines, microcomputer hydraulic universal testing machines, and microcomputer pressure machines. Can conduct tensile, compression, bending, shear, tear, and peel tests. Using a PC and interface board for data collection, storage, processing, and printing of test results. Can calculate parameters such as maximum force, yield force, average peel force, maximum deformation, yield point, elastic modulus, etc; Capable of curve processing, multi-sensor support, graphical interface, flexible data processing MS-ACCESS 2003 database support makes the system more powerful.

M223C adopts Visual Studio Net development, supporting Windows XP/Win7 operating system;

Supports 9 types of text: Simplified Chinese, Traditional Chinese, English, Spanish, Russian, Japanese, French, German, Portuguese, with arbitrary switching. The database field display name of the experimental data is automatically translated according to the selected text, making the data easy to browse in local text, basically meeting the needs of the testing machine worldwide;

Supports three types: SI International Standard Units Kg cm units Lb Inch English units, 6 common unit systems: N-mm-MPa kN-mm-MPa、gf-cm-kgf/cm2、kgf-cm-kgf/cm2、Lb-Inch-kpsi、kP-Inch-kpsi, Convenient unit switching. Meet the use of standards in different regions.

1. Test standard modular function: providing users with testing for setting the required applications

Standard settings, covering GB ASTM, DIN, JIS, BS, etc. Test standard specifications.

2. Sample data: Provide users with all sample data set, input at once

Data is permanently reused. And it is possible to add and modify formulas on its own to improve the compatibility of test data.

3. Dual report editing: Fully open for users to edit reports for testers to choose from

Favorite report format (testing program adds built-in Excel reports)

The editing function has expanded the pattern of single professional reports in the past

4. Each length, strength unit, and display digit are dynamically swapped, and the strength unit T is used Kg、N、KN、g、lb, Deformation unit: mm cm、inch。

5. Auto Scale, which automatically optimizes the graph curve scale

Best scale display. And it can dynamically switch between graphics in real-time during testing. have

Load displacement, load time, displacement time, and stress-strain

Load -2 point extension diagram and multi curve comparison.

6. The test results can be in Excel format

Output according to form.

7. After the test is completed, it can be automatically saved or manually saved. After the test is completed, it can automatically calculate the maximum force, upper and lower yield strength, hysteresis loop method, gradual approximation method, non proportional elongation strength, tensile strength, compressive strength, constant elongation strength at any point, constant load extension at any point, elastic modulus, elongation rate, maximum and minimum values of the peeling interval, average value, net energy, return energy, total energy, bending modulus, x% load of the breakpoint displacement, X% load of the breakpoint load, and so on.

Data backup: Test data can be saved in any hard disk partition.

8. Language: Simplified Chinese.

9. The software has a historical test data demonstration function.

4、 Testable items

(1) Normal test items: (Normal display value and calculated value)

● Tensile stress ● Tensile strength

● Breaking strength ● Elongation at break

● Constant tensile stress ● Constant stress elongation rate

● Constant stress value ● Tear strength

● Force value at any point ● Elongation at any point

● Extraction force ● Adhesion force and peak value calculation

● Pressure test ● Adhesive force peeling force test

● Bending test ● Pulling force puncture force test

(2) Special testing items:

1. Elastic coefficient, also known as Young's modulus of elasticity

Definition: The ratio of normal stress components in the same phase to normal strain. To determine the coefficient of material rigidity, the higher the value, the stronger and tougher the material.

2. Example limit: The load can maintain a proportional relationship with elongation within a certain range, and its maximum stress is the specific limit.

3. Elastic limit: The maximum stress that a material can withstand without permanent deformation.

4. Elastic deformation: After removing the load, the deformation of the material completely disappears.

5. Permanent deformation: After removing the load, the material still retains deformation.

6. Yield point: When the material is stretched, the deformation increases rapidly while the stress remains constant, and this point is called the yield point. The yield point is divided into upper and lower yield points, and generally the yield point above is used as the yield point.

Yield: When the load exceeds the proportional limit and is no longer proportional to elongation, the load will suddenly decrease, and then fluctuate up and down over a period of time, causing significant changes in elongation. This phenomenon is called yield.

7. Yield strength: The quotient obtained by dividing the load at which the permanent elongation reaches a specified value during tension by the original cross-sectional area of the parallel part.

8. Spring K value: The ratio of the force component in the same phase as the deformation to the deformation.

9. Effective elasticity and hysteresis loss:

On a tensile testing machine, when the specimen is stretched at a certain speed to a certain elongation or to a specified load, the effective elasticity is determined by measuring the percentage of work recovered during contraction to work consumed during extension; The percentage of the energy lost during the elongation and contraction of the sample compared to the work consumed during elongation is called the hysteresis loss.

5、 Main counting indicators

1. Load element: 0-20kN interval optional configuration

2. Power resolution: 1/500000

3. Strength accuracy: ≤ 0.1%

4. Power amplification factor: 7-stage automatic switching

5. Displacement resolution: 1/1000

6. Displacement accuracy: ≤ 0.1%

7. Speed range: 0.1-500mm/min (special testing speeds can also be customized according to customer needs)

8. Effective walking space: 900mm (excluding grippers, special testing space can also be customized according to customer needs)

9. Power supply: É 220V50HZ.

10. Power: Approximately 400W

11. Machine size: approximately 710 x 440 x 1550 mm (length x width x height)

12. Machine weight: approximately 180 kg

Product Configuration List

|

Number |

name |

producing area |

Remarks |

数量 |

|

1 |

sensor |

China |

Anhui Tianguang(20KN) |

一 个 |

|

2 |

ball screw |

China |

Zhejiang Changhua |

二 根 |

|

3 |

Servo driver |

China |

Hangzhou Navigation |

一 台 |

|

4 |

servo motor |

China |

Hangzhou Navigation |

一 台 |

|

5 |

Gearbox |

China |

Cast aluminum |

一 台 |

|

6 |

Synchronous belt |

China |

Taizhou Jiujiang |

一 根 |

|

7 |

Motherboard |

China |

Our company |

一 块 |

|

8 |

Software |

China |

Our company |

一 份 |

|

9 |

Fixture |

China |

Our company |

一 付 |

|

10 |

Computer |

China |

Our company's standard configuration |

一 台 |

|

|

|

|

|

|

|

|

|

|

|

|

|

Note: The material treatment process of the bottom plate includes annealing treatment of 45 # steel, and the degree of deformation does not exceed 0.2MM. |

||||

Tel:15231476158

Tel:15231476158 Mailbox:948064885@qq.com

Mailbox:948064885@qq.com QQ:948064885

QQ:948064885 Add:Room 211, Juntai Fortune Plaza, Shuangtashan Town, Shuangluan District, Chengde City, Hebei Province

Add:Room 211, Juntai Fortune Plaza, Shuangtashan Town, Shuangluan District, Chengde City, Hebei Province