1、 Product Overview

This machine is used for measuring the mechanical properties of various thermosetting and thermoplastic plastics and plastic pipes, including tensile modulus, bending modulus, compression modulus, yield strength, tensile strength, fracture strength, elongation at break, compressive stress, compressive strain, shear, peeling, bracing, tearing, penetration, etc. It is suitable for material analysis and inspection in industries such as engineering plastics, reinforced nylon, modified plastics, plastics, profiles, plastic pipes, plastic sheets, and films.

This testing machine can be used for material data testing by scientific research institutions, colleges and universities, production inspection institutes at all levels, and material production factories.

2、 Execution standards

|

Standard number |

Standard name |

|

GB/T 16491-2008 |

Electronic universal testing machine |

|

GB/T 1040.1-2018 |

Determination of tensile properties of plastics Part 1: General principles |

|

GB/T 1041-2008 |

Determination of compressive properties of plastics |

|

GB/T 9341-2008 |

Test method for bending performance of plastics |

|

IS0 527-1993 |

Determination of tensile properties of plastics |

|

GB/T 18997.1-2020 |

Aluminum-plastic composite pressure pipes - Part 1: Aluminum pipes - Lap welded aluminum-plastic pipes |

|

GB/T 2791-1995 |

Test method for peel strength of adhesive T - Flexible materials on flexible materials |

|

GB/T 328.8-2007 |

Test methods for building waterproofing membranes Part 8: Tensile properties of asphalt waterproofing membranes |

|

GB/T 15788-2017 |

Geosynthetic materials - Wide strip tensile test method |

|

GB/T 1040.3-2006 |

Determination of tensile properties of plastics Part 3: Test conditions for films and sheets |

|

GB/T 19806-2005 |

Extrusion peel test for polyethylene electrofusion components of plastic pipes and fittings |

|

ISO 604-2002 |

Plastics - Determination of compressive properties |

|

ISO 178:2019 |

Plastics — Determination of flexural properties |

|

ISO 1209-1-2007 |

Rigid cellular plastics - Determination of flexural properties - Part 1: Basic bending test |

|

ISO 1209-2-2007 |

Rigid cellular plastics - Determination of flexural properties - Part 2: Determination of flexural strength and apparent flexural modulus of elasticity |

|

ASTM D 638-2008 |

Standard Test Method for Tensile Properties of Plastics |

3、 Functional characteristics

1. The transmission part of the machine adopts a complete set of imported fully digital AC servo systems, a high-strength gantry frame structure, and adopts a segmented linear correction method to ensure high accuracy and stability of the force value detection part. High precision large deformation extensometers and small deformation extensometers can be optionally equipped; Accurately measure the deformation within the spacing between the sample markings. This machine has a simple and beautiful design, high accuracy, low noise, and convenient operation. It can provide a variety of fixtures for users to choose from.

Using high-quality imported load sensors, the collection part adopts a segmented linear correction method to ensure high accuracy and stability of the load detection part. The sensor adopts intelligent and digital design, breaking away from traditional collection and transmission methods, greatly improving the sampling accuracy and stability of the sensor; By adopting new sensor recognition technology, it is possible to automatically identify the installation status, sensor properties, and sensor coefficients of the sensor; The modification of sensors does not require software settings;

3. Supports multiple languages such as Chinese, English, French, and German to achieve software internationalization; It provides various curves such as stress-strain, load displacement, strain time, displacement time, and many other functions such as coordinate system configuration; Embedded data analysis and comparison software, export experimental data and test reports to Excel. Provided auxiliary analysis methods for user product development; Using network technology to achieve diagnosis and upgrading, it can be updated and upgraded online for free at any time through the network.

4、 Technical parameters

|

model |

XWW-20B series |

|

|

|

Maximum test force |

20kN |

|

Accuracy level |

Level 0.5 |

|

|

Test force measurement range |

0.5%~100%FS |

|

|

Relative error of experimental force indication |

±0.5% |

|

|

Experimental resolution |

0.5/200000 |

|

|

Deformation measurement range |

0.4~100%FS |

|

|

Relative error of deformation indication |

±0.5% within |

|

|

Deformation resolution |

1/200000 |

|

|

Large deformation measurement range |

Maximum value 900mm |

|

|

Relative error of large deformation indication |

±0.50% within |

|

|

Large deformation resolution |

0.0125mm |

|

|

Measurement of bending deflection using a measuring instrument |

15mm |

|

|

Resolution of bending deflection measuring instrument |

0.001mm |

|

|

Accuracy of bending deflection measuring instrument |

0.005mm |

|

|

Relative error of displacement indication of crossbeam |

±0.50% within |

|

|

Displacement resolution |

0.0001mm |

|

|

Relative error of deformation control rate |

When the speed is less than 0.05% FS, it is within ± 2% of the set value; When the speed is ≥ 0.05% FS, it is within ± 0.5% of the set value |

|

|

Cross beam speed adjustment range |

0.001~500mm/min |

|

|

Relative error of beam speed |

When the speed is less than 0.05 mm/min, within ± 1.0% of the set value; When the speed is ≥ 0.05 mm/min, within ± 0.5% of the set value; |

|

|

Instrument parameters and Device Introduction |

Maximum stretching stroke |

900mm |

|

Effective test width |

415mm |

|

|

Power supply |

220VAC-15%~220VAC+10% 50Hz 1kVA |

|

|

Host size |

800mm×480mm×1900mm |

|

|

Host weight |

Approximately 250kg |

|

|

Servo motor set |

Panasonic servo motor set from Japan |

|

|

sensor |

American transmission force sensor |

|

|

Gearbox |

Topforth planetary gearbox from Germany |

|

|

encoder |

Omron, Japan |

|

|

ball screw |

Taiwan ball screw |

|

|

computer |

Lenovo brand computers |

|

|

printer |

HP brand printer |

|

|

Instrument standard configuration |

main engine |

one |

|

Large deformation extensometer |

one |

|

|

Lenovo Computer |

one |

|

|

HP Printers |

one |

|

|

Stretching fixture |

one(Jaws 0-7mm) |

|

|

Bending fixture |

one |

|

|

20KN sensor |

one |

|

|

500N sensor |

one |

|

|

Power cord |

one |

|

5、 Attention

1. This machine meets the requirements of GB/T 16491-2008 "Electronic Universal Testing Machine" standard;

2. Choosing an additional force value sensor can expand the measurement range

3. The force control rate and deformation rate are both related to the material of the specimen, and their range cannot exceed the range of displacement rate adjustment;

To avoid deformation of the force sensor, during long-term holding tests, the test force should not exceed 50% of the full range of the sensor;

The actual effective space is the test space after installing the stretching fixture. If the fixture is different, the stretching space data will also follow. Changes.

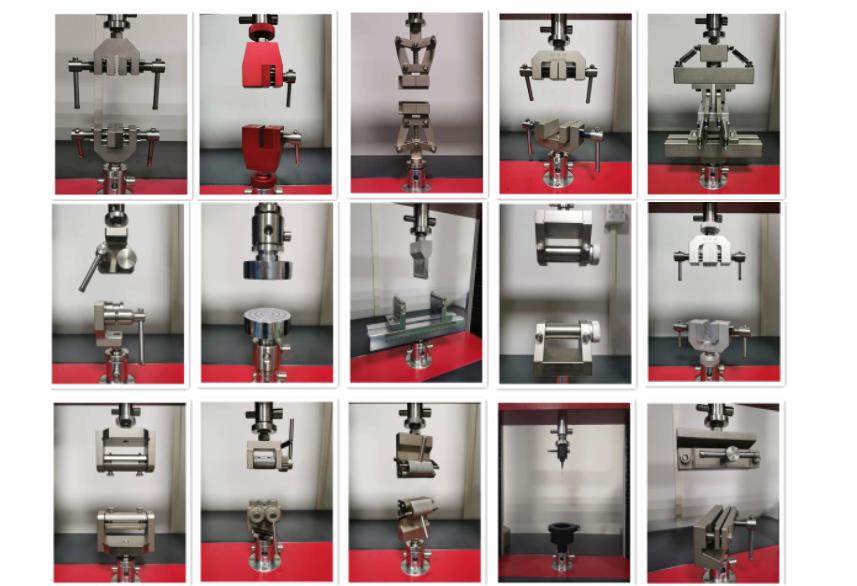

6、 Fixture series

The above fixtures are based on the actual product

Tel:15231476158

Tel:15231476158 Mailbox:948064885@qq.com

Mailbox:948064885@qq.com QQ:948064885

QQ:948064885 Add:Room 211, Juntai Fortune Plaza, Shuangtashan Town, Shuangluan District, Chengde City, Hebei Province

Add:Room 211, Juntai Fortune Plaza, Shuangtashan Town, Shuangluan District, Chengde City, Hebei Province