1、 Introduction

The longitudinal shrinkage rate is an important indicator of the performance of plastic pipe products. It reflects the stable performance of plastic pipe products in terms of longitudinal plastic deformation under thermal influence. Its measurement is of great significance in improving the product's ability to withstand changes in temperature, sunlight, and other heat sources during use, as well as extending the product's service life. However, due to the diversity of methods for measuring the longitudinal shrinkage rate, our detection accuracy is often affected by improper operation or lack of attention to key points.

2、 Applicable scope

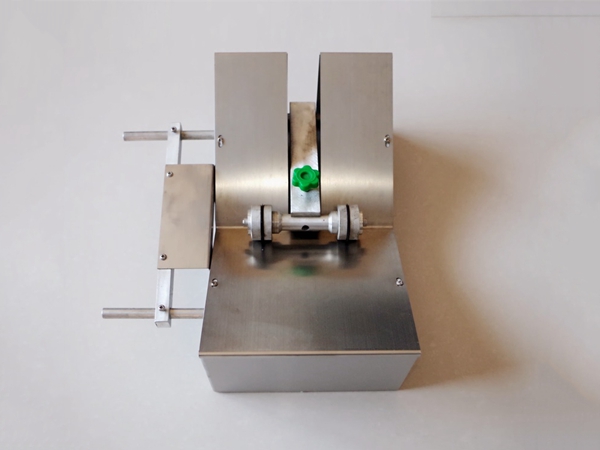

According to GBT 6671-2001 Determination of longitudinal shrinkage rate of thermoplastic pipes, the longitudinal shrinkage rate of plastic pipes is determined. Place the standard sample to be drawn on two rollers, adjust the distance between the two brushes to 100mm, and adjust the distance between one brush and one end of the tube to 10mm. Then, turn the handwheel to draw two equally spaced closed circumferential lines (this length is L0 between the two lines before the experiment) on the sample. Put the preprocessed sample into an oven and heat it up according to the standard requirements, then cool it down and test the distance between the two marked lines of the pipe with LI

3、 Technical parameters

1. Blade thickness: 2mm

2. Blade roller spacing: 100mm ± 0.1mm

3. Net weight: 9KG

4. Gross weight: 11.25KG

4、 Usage

4.1. Carefully lift the roller and place the specimen to be drawn under the two rollers (the distance between the rollers has been adjusted to 100mm ± 0.1 in advance), with one end pressing against the baffle, then lower the roller and gently press the center position of the two rollers with your hand.

4.2 Slowly rotate the pipe specimen and draw two closed circular lines with an equal distance of 100mm on the surface of the specimen by rotating it once. If the marking feels light and unclear, you can repeat the rotation for one cycle.

4.3. Measure the spacing L0 between the markings at (23 ± 2 ℃) with an accuracy of 0.25mm.

5、 Processing of experimental results

Vertical shrinkage rate T=| L0 |/L0X100

Explanation: We mark two circular lines with a distance of 100mm for each section of the sample, and ensure that one of the lines is at least 10mm away from either end of the sample. After drawing the line, we should use the measurement result as the original standard distance for the disease measurement.

Set the oven to the required 150 ℃, and when the oven reaches the specified temperature, we put in the prepared sample. Measure once and use the measurement result as the original gauge distance.

Set the oven to the required 150 ℃, and when the oven reaches the specified temperature, we put in the prepared sample. It should be noted that after placing the sample, the oven should return to the set temperature within 15 minutes. Therefore, we cannot place too many samples, they should be within the range that the oven can withstand, and the action should be slightly faster to prevent the temperature inside the oven from dropping too much.

There are two methods for placing specimens here: the first method is to suspend the specimen and hang it in the oven. This suspension point should be at the far end of the marking line, and the specimen should not touch the bottom and wall of the oven. The second type of flat sample should be placed on a flat plate with a layer of talcum powder and then placed in an oven.

Here, we suspend two sets of samples in an oven for heating, while the other two sets are placed flat in the oven for heating. Turn off the oven and start timing when the oven temperature rises to 150 ℃.

Here, according to the requirements, it needs to be left for 60 minutes. After 60 minutes, we took the specimens out of the oven and placed one set of suspended specimens flat on a smooth wooden countertop, while the other set was placed on a smooth granite countertop. The other two groups are also placed separately. When the sample is completely cooled to (23 ± 2 ℃), we will measure the large or small distance between the markings. Here, we should make multiple measurements, choose the value where Li changes significantly relative to the original gauge length, and then proceed with the calculation.

Tel:15231476158

Tel:15231476158 Mailbox:948064885@qq.com

Mailbox:948064885@qq.com QQ:948064885

QQ:948064885 Add:Room 211, Juntai Fortune Plaza, Shuangtashan Town, Shuangluan District, Chengde City, Hebei Province

Add:Room 211, Juntai Fortune Plaza, Shuangtashan Town, Shuangluan District, Chengde City, Hebei Province