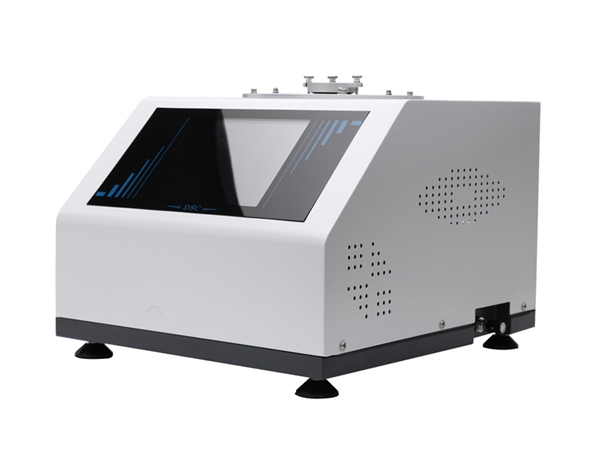

A new breakthrough has been made in the structural design and flexibility of differential scanning calorimeter. The measuring unit is a cylindrical 3D heated silver furnace body, which is embedded with heating wire and external cooling equipment. The high thermal conductivity of the silver furnace ensures the temperature uniformity inside the furnace. The integrated electronic flow control system ensures flow control in different purge and protection atmospheres. Its air-tight structural design allows the outlet end of the furnace to be connected to infrared or mass spectrometry for the composition analysis of the product gas.

Depending on the application field and actual needs, users of differential scanning calorimeters can freely choose two different types of sensors. The time constant of the τ sensor is only 0.6 seconds, which ensures a good separation ability for overlapping thermal effects. The μ-type sensor has a sensitivity ten times higher than that of ordinary sensors under the premise of ensuring the peak separation ability, which is especially suitable for the research of small sample size in the fields of drugs, food, biological materials, liquid crystals and so on.

Differential scanning calorimeter is a thermal analysis technique that measures the temperature and heat flow of a material in relation to changes in specific heat capacity, characterizing them in relation to time and temperature. Such tests can quantitatively and qualitatively provide information about physical and chemical changes, including endothermic (energy consumption) and exothermic (energy production) processes, or changes in heat capacity. Differential scanning calorimeters are particularly suitable for analyzing food systems because they are often heated or cooled during processing. The calorimetric information obtained from the differential scanning calorimeter can be directly used to understand the thermal transition that a food system may undergo during processing or storage. The differential scanning calorimeter is easy to operate and requires no special sample preparation in most cases.

In order to ensure the normal use of the differential scanning calorimeter, we must clarify the precautions in the use of the differential scanning calorimeter.

1. Have a general understanding of sample properties before testing. First of all, the user should ensure that the sample within the test temperature range does not occur thermal decomposition, does not react with metal aluminum, no corrosion. If the sample to be measured can produce a large amount of gas during the heating process, or can cause an explosion, can not use the instrument.

2. Check whether all the connections of differential scanning calorimeter are correct, whether the gas used is sufficient, and whether the tools are complete.

3. In the test, if the aluminum crucible is selected as the sample dish, the high temperature of the test should not exceed 550℃. If the high temperature in the experiment exceeds 550℃, the ceramic crucible can be used. The bottom of the crucible should be flat, without zigzag or curved, otherwise the heat transfer is poor.

4. The laboratory room temperature is controlled at 20℃-30℃, and the experimental result degree and repeatability are high when the temperature is relatively constant. When the room temperature is high, the air conditioner should be turned on to ensure that the ambient temperature is relatively constant in a short time.

5, in order to ensure the accuracy of the test results, the use of the instrument first air burning (without any sample and reference) for about 30 minutes.

6, the instrument is not used for a long time, and when it is used again, be sure to air burn two to three times, you can set the temperature to 400℃, the rate to 10℃/min, the constant temperature to 0min, press the "Run" key.

7, when preparing DSC samples, do not sprinkle the sample on the edge of the crucible, so as not to pollute the sensor and destroy the instrument. The bottom of the crucible and all outer surfaces should not be attached to samples and impurities to avoid affecting the experimental results.

8, the sample dosage should be appropriate, not too much, not too little. Solid samples are generally about 20mg. The liquid sample should not exceed two-thirds of the crucible capacity. If the sample dosage is otherwise required, determine the dosage according to the requirements.

9, the sample dosage should be appropriate, not too much, not too little. Solid samples are generally about 20mg. The liquid sample should not exceed two-thirds of the crucible capacity. If the sample dosage is otherwise required, determine the dosage according to the requirements.

10. The crucible is placed in a fixed position in the support, and the sample should be evenly laid at the bottom of the crucible when the amount of sample is small, not piled on one side; If the sample is a particle, it needs to be placed in the center of the crucible.

11, do not use hard objects to clean the sample tray and experimental area, so as not to cause irreversible damage to the instrument; If there is dust or other powdery debris in the experimental area, the ear ball should be used to blow it clean, and be careful to blow it with your mouth and lose your eyes; When the experimental area is seriously polluted, you can set the temperature to 500℃, the rate to 20℃/min, the constant temperature to 0min, and press the "Run" key.

12, the process of data collection should avoid obvious vibration around the instrument, it is strictly prohibited to open the cover, slight touch the front of the instrument will produce obvious peaks and valleys on the DSC curve; Do not adjust the flow rate of the purified gas during the collection of data, because a slight change in the flow rate of the gas will have an impact on the DSC curve.

13, after the end of the experiment, be careful of the DSC stove cover, handle gently with tweezers, to avoid being hot or the stove cover damage; Disconnect the data cable and turn off the software before turning off the instrument. To prevent online, communication errors.

Tel:15231476158

Tel:15231476158 Mailbox:948064885@qq.com

Mailbox:948064885@qq.com QQ:948064885

QQ:948064885 Add:Room 211, Juntai Fortune Plaza, Shuangtashan Town, Shuangluan District, Chengde City, Hebei Province

Add:Room 211, Juntai Fortune Plaza, Shuangtashan Town, Shuangluan District, Chengde City, Hebei Province